Managing diabetes can be a troublesome process. For people living with diabetes, the traditional method of monitoring glucose involves finger pricking. Continuous glucose monitoring systems are an alternative, but they are expensive.

Scientists have used screen printing, photolithography, and other traditional manufacturing practices to develop flexible, wearable devices that conform to patients’ skin. These devices would monitor the glucose in the user’s sweat and other bodily fluids. Although these methods work, they have several drawbacks like, requiring the use of harmful chemicals and clean-room processing, which is also very expensive.

Now, Washington State University (WSU) researchers have created a 3D-printed glucose biosensor for use in wearable monitors. The researchers said their work may lead to better glucose monitors for millions of diabetes patients globally. These sensors also reduce costs and cut down waste like expensive cleanroom processing and harmful chemicals, according to Washington State, reports Science Daily.

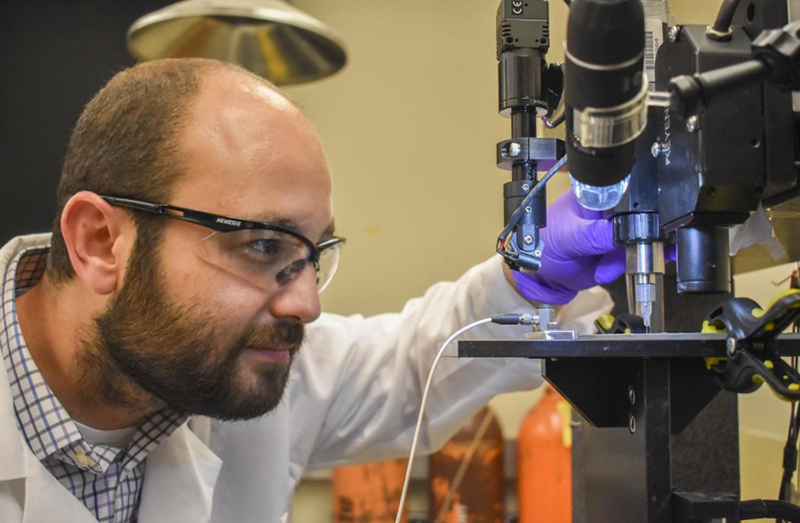

The research team was led by Arda Gozen and Yuehe Lin, faculty in the School of Mechanical and Materials Engineering at WSU. The findings were published in the journal Analytica Chimica Acta.

Using 3-D Printing to Create a Glucose Biosensor

The researchers used a 3-D printing method called direct-ink-writing (DIW) to create their biosensor. With DIW, the printer prints inks’ out of nozzles to create precise and intricate designs at tiny scales.

Researchers discovered that their 3D‑printed sensors performed better at picking up glucose signals than the conventional method of using electrodes, and the sensors are also more customizable for the variety of people’s biology.

“3-D printing can enable manufacturing of biosensors tailored specifically to individual patients,” said Gozen.

Because the 3D printing uses only the amount of material needed, there is also less waste in the process than traditional manufacturing methods.

“This can potentially bring down the cost,” said Gozen.

Integrating the printed biosensors with electronic components on wearable devices would enable large-scale use. To cut down costs even more, the manufacturers could use the same 3D printer nozzles used for printing the sensors to print components of the wearable device.

“Our 3-D printed glucose sensor will be used as wearable sensor for replacing painful finger pricking. Since this is a noninvasive, needleless technique for glucose monitoring, it will be easier for children’s glucose monitoring,” said Lin.