With the rising popularity of wearable devices, smartwatches are no longer the coolest wearables around. Biotech is now becoming more and more popular. Devices such as vital sign monitoring stickers, brain wave tracking pain relief goggles, and mind reading glasses are taking over the industry.

Researchers in South Korea have now developed fully-transformable electrode materials that also feature a high electric conductivity, reports Institute for Basic Science. The joint research team was led by Prof. Jang-Ung Park at the Center for Nanomedicine within the Institute for Basic Science (IBS) in Daejeon, South Korea, and Prof. Chang Young Lee at the Ulsan National Institute of Science and Technology (UNIST) in Ulsan, South Korea. The study was reported in the journal Nano Letters.

Notably, this novel composite is super-thin, 5 micrometers in diameter, which is half of the width of conventional wire bonding. By enabling ever-slimmer 3D interconnects, this study can help to revolutionize the physical appearance of smart gadgets, in addition to reinforcing their technical functions.

The researchers used liquid metals (LM) as the main substrate since LMs are highly stretchable and have relatively high conductivities similar to solid metals. To improve the mechanical stability of the metal liquid, carbon nanotubes (CNT) were dispersed uniformly.

“To have a uniform and homogeneous dispersion of CNTs in liquid metal, we selected platinum (Pt), for having a strong affinity to both CNT and LM, as the mixer and it worked,” said Young-Geun Park, the first author of the study.

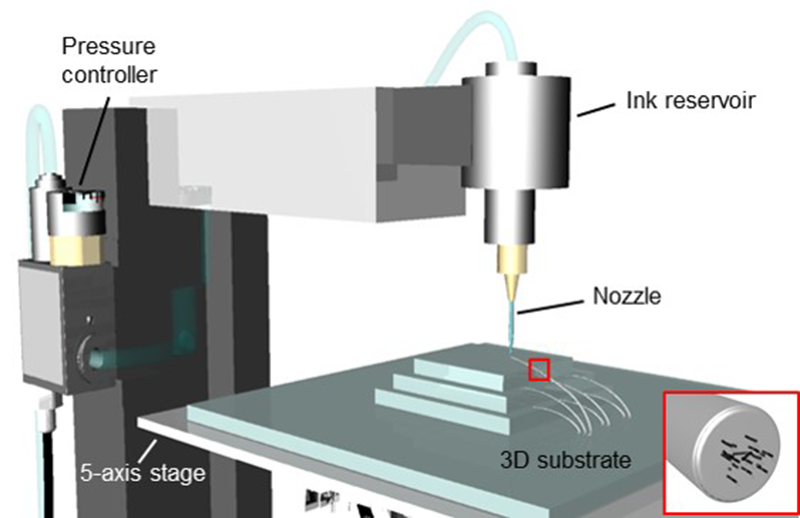

This team also demonstrated a new interconnection technology that can form a highly conductive 3D structure at room temperature: For having a high conductivity, the new system does not require any heating or compressing process. Also, the soft and stretchable nature of the new electrode makes it easy to come through the nozzle in a fine diameter. The research team used a nozzle for the direct printing of various 3D patterning structure.

“Forming high-conductivity 3D interconnections at room temperature is an essential technology that enables the use of various flexible electronic materials. The wire bonding technology used in existing electronic devices forms interconnects using heat, pressure, or ultrasonic waves that can damage soft, skin-like devices. They have been a great challenge in the manufacturing process of high-performance electronic devices,” Park explains. He noted that the pointed nozzle also allows reshaping of the preprinted pattern into various 3D structure, thus having an electrode work like a “switch” to turn on and off power.

Read more 3D Printing Hits the Big Screen as it Brings Futuristic Wearables to Life in Black Panther

“We may soon be able to say goodbye to those bulky skin-based interfaces as this freely-transformable, super-thin 3D interconnection technology will come as a big breakthrough to the industry’s efforts to produce ever compact and slim gadgets,” noted Park.